So while wrapping up some of the EV related items ( still have to cut the sprocket guard and bottom plate from sheet metal and ordered a 46T rear sprocket), I gave the Honda GL500i a bit of attention this morning.

Looking at some possible reasons it was running cold on the right cylinder (it is a 2 cylinder 500 cc engine) I made changes to the air filter, the carb knob below the carbs, and the right spark plug connection.

The air filter, pictured below, is a mess. Not sure which previous owner thought this was a good idea but the whole thing reeks of engine fumes. Ordered a new one today.

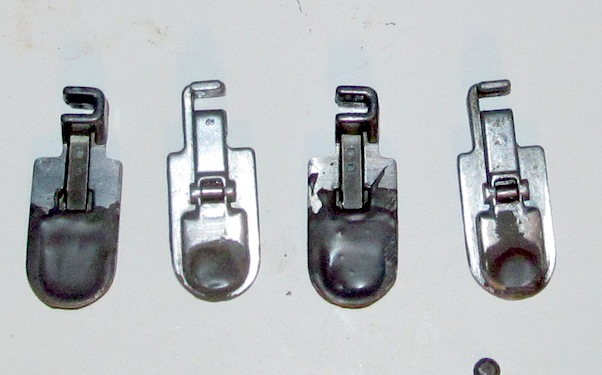

Adjusting the knob below the carbs allowed the motor to idle at a higher rpm without adjusting the choke. Nice. Even nicer when I pulled the spark plug connection out and as soon as i broke the connection, but had not removed the cable, spark was made and the right cylinder fired up as well. The engine sounds a lot better that way.

Was able to ride it up hill in my driveway twice before taking it down the street and around the neighborhood & then back up my driveway (steep and short ends). Just need to fix the fork seal leaks, the leak by the clutch pedal, and figure out what the rear leak is from. As it is a shaft drive the rear leak could be from the connection to the wheel though it is not obvious from just looking at the tire (but the leak is only evident on the bottom half of the tire).